Introduction

CO2 mineralization represents a transformative strategy in the fight against climate change, converting atmospheric CO2 into solid carbonates through reactions with alkaline minerals. This process, which mimics natural weathering but at an accelerated pace, holds immense potential for permanent carbon storage. According to recent studies, it could remove up to 1 gigaton of CO2 annually by 2035 and 10 gigatons by 2050 with adequate funding [1].

Projects like CarbFix in Iceland exemplify this, capturing 12,000 tonnes of CO2 yearly and planning expansions to 34,000 tonnes by 2025 [1]. However, issues like water consumption—requiring 25 tons per ton of CO2 in CarbFix—raise environmental concerns [1]. Drawing from expert analyses, this section overviews the technology’s mechanisms, integrating insights from web sources and social media to highlight trends toward market growth projected at USD 3.5 billion by 2033 [G8].

Key Innovations in CO2 Mineralization

Recent technological breakthroughs are enhancing CO2 mineralization’s efficiency. Plasma-liquid interactions, for instance, accelerate reactions by controlling carbonate polymorphs through optimized electron temperatures in nonthermal plasmas [2].

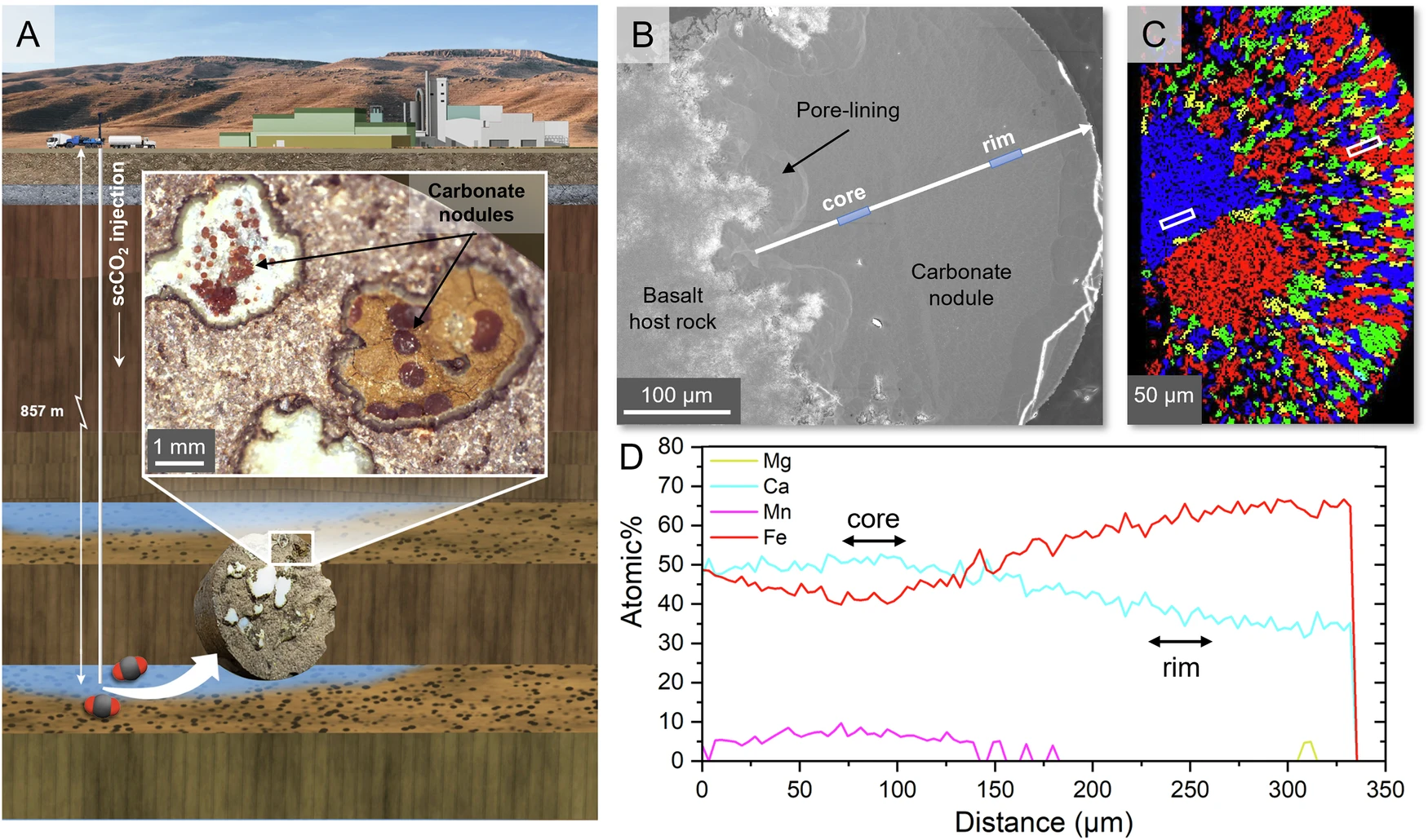

This allows for directed formation of stable minerals, addressing slow natural rates. Another advance involves heat-treating peridotite minerals to boost reactivity, enabling rapid CO2 capture without high energy inputs [6]. Studies on complex carbonate phases reveal how atomic structures facilitate geologic trapping, improving long-term integrity [3].

Expert perspectives from web analyses emphasize synergies with direct air capture (DAC), where mineralization provides permanent storage [G10]. on social media, discussions highlight enhanced rock weathering with basalt, noting finer particles improve efficiency in soils [G posts on geoengineering]. However, critics point to energy demands, with some posts questioning scalability in non-volcanic regions [G posts from skeptics]. Balanced views suggest integrating industrial wastes like steel slag could cut costs and repurpose materials [G14].

The CarbFix Project: A Real-World Case Study

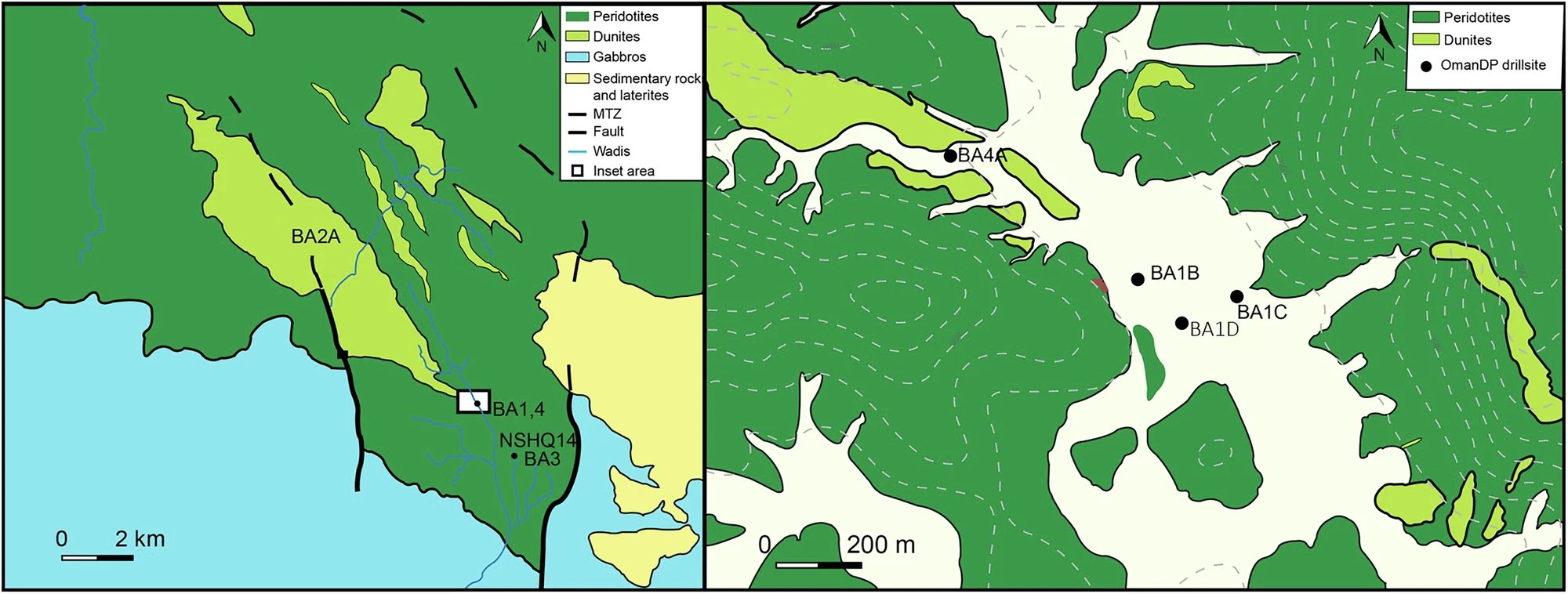

Iceland’s CarbFix project stands as a flagship example, injecting CO2-dissolved water into basalt formations for mineralization within two years [G1, G3]. Currently handling 12,000 tonnes annually, the Silverstone expansion targets 34,000 tonnes from 2025, aligning with Iceland’s net-zero ambitions [1]. Funded by the EU Innovation Fund, it recently secured Europe’s first onshore CO2 storage permit [G12, G13].

Social media buzz on social media praises CarbFix’s “gas-to-stone” innovation, with posts from officials like India’s Hardeep Singh Puri discussing potential collaborations [G15]. Historical X threads from NPR in 2019 resurface, underscoring early optimism [G17-G20]. Yet, analyses critique water usage, proposing brine recycling as a solution to reduce freshwater needs by up to 70% [G original insights]. Reports on semi-continuous ex situ methods show promise for broader applications [4].

Challenges and Balanced Viewpoints

Despite potential, CO2 mineralization faces hurdles. Geological limitations restrict it to basalt-rich areas, and reservoir characterization remains challenging [1, 5]. Economic barriers include high initial costs, though waste integration could mitigate this [G14]. Expert opinions on social media vary: optimists like Geoengineering Info tout ERW for agriculture [G posts], while skeptics highlight inefficiencies in pilots [G posts from critics].

Balanced analyses from IEAGHG webinars stress site-specific solutions, such as plasma enhancements for polymorphic control [2, G posts from IEAGHG]. Constructive perspectives focus on policy support, with EU permits enabling expansion [G12]. Innovations like heat activation offer concrete paths to scalability [6].

Emerging Trends and Solutions

Market trends indicate growth, with CO2 mineralization integrating into renewables like geothermal energy [G6, G7]. Cleantechnica reports on DAC-mineralization hybrids scaling up [G9, G10]. on social media, posts discuss global adoption, including China’s ERW pilots [G posts]. Solutions under study include AI-optimized modeling for wider applicability and waste-to-concrete conversions, potentially slashing cement emissions by 20-30% [G original insights].

KEY FIGURES:

- CO2 Mineralization Potential: Accelerated mineralization could remove up to 1 gigaton of CO2 annually by 2035 and 10 gigatons by 2050 with sufficient investment[1].

- CarbFix Project: Captures around 12,000 tonnes of CO2 annually, with plans to scale to 34,000 tonnes per year starting in 2025[1].

- Water Usage: Approximately 25 tons of water per ton of CO2 are used in the CarbFix process[1].

RECENT NEWS:

- CarbFix Expansion: The Silverstone project aims to increase CO2 capture to 34,000 tonnes per year, contributing to Iceland’s emissions reduction goals[1].

- Advancements in Plasma Technology: Recent studies have shown that plasma–liquid interactions can enhance CO2 mineralization by directing the formation of specific carbonate phases[2].

STUDIES AND REPORTS:

- Accelerated CO2 Mineralization: A study on plasma–liquid interactions demonstrates how modifying electron temperatures in nonthermal CO2 plasmas can accelerate CO2 mineralization and control carbonate polymorphs[2].

- Geological Storage Review: A review highlights the potential of carbonate and basalt formations for CO2 storage, emphasizing challenges such as reservoir characterization and long-term integrity[1].

- Complex Carbonate Phases: Research on field-scale demonstrations of CO2 mineralization explores the atomic structure and morphology of carbonates, highlighting their role in geologic CO2 trapping[3].

TECHNOLOGICAL DEVELOPMENTS:

- Heat Treatment of Minerals: Recent breakthroughs involve using heat to activate common minerals, making them highly reactive to CO2 for rapid and cost-effective capture[6].

- Plasma–Liquid Interactions: This technology enhances CO2 mineralization by optimizing plasma discharge parameters to control the formation of specific carbonate phases[2].

MAIN SOURCES:

-

- https://pubs.acs.org/doi/abs/10.1021/acs.energyfuels.4c04424 – A critical review on challenges and future outlooks for CO2 storage in carbonate and basalt formations.

- https://pubs.rsc.org/en/content/articlelanding/2025/cp/d5cp01196e – Accelerated carbon dioxide mineralization and polymorphic control facilitated by nonthermal plasma bubbles.

- https://www.nature.com/articles/s43247-025-02273-6 – Complex carbonate phases drive geologic CO2 mineralization.

- https://scijournals.onlinelibrary.wiley.com/doi/abs/10.1002/ese3.70125 – Semi-Continuous Ex Situ Carbon Dioxide Mineralization.

- https://ieaghg.org/publications/co2-storage-by-mineral-carbonation/ – CO₂ Storage by Mineral Carbonation.

- https://www.nature.com/articles/s43247-025-02509-5 – Rapid mineralisation of carbon dioxide in peridotites.